PSA Antwerp Cuts Operational Costs by 33% by Optimizing Their Business in Real Time

33%

reduction in operational costs

Challenge

- Service outages created costly backlogs that cascaded through all business operations.

- Inability to provide an up-to-date view of business operations as databases couldn’t ingest and process huge volumes of high-velocity data.

- Inefficient use of expensive machinery and resources increased cost of ownership.

Solution

- Deployed Hazelcast Community Edition to enable real-time dashboard view that allows planners to optimise operations in-the-moment.

- Deployed Hazelcast Enterprise Edition to guarantee a continuous, real-time, dashboard view during software upgrades and planned downtime.

- Other capabilities like Hazelcast Management Centre and Security Suite enable the secure and effective monitoring, management, and analysis of the cluster.

Customer Success

- 33% operational cost saving for horizontal transport predicted with zero downtime benefit.

- Continuous real-time view allows planners to instantly streamline business processes, maximising the productivity of every asset and resource at the most granular level.

- Hazelcast Platform helps futureproof existing architecture by enabling predictable performance and linear scalability.

“We are very happy with our relationship with Hazelcast. We are impressed with how Hazelcast engages with us and provides its expertise when we need it. They have left a lasting, positive impression with their dedication to customer satisfaction.”

— Patrick Snelders, Regional Technology Manager, Group Yard Crane Automation Specialist

How can your business benefit from real-time insights?

Industry

Port operator

Year Founded

2002

Product

Hazelcast Platform

Result

33% operational cost savings

Introduction

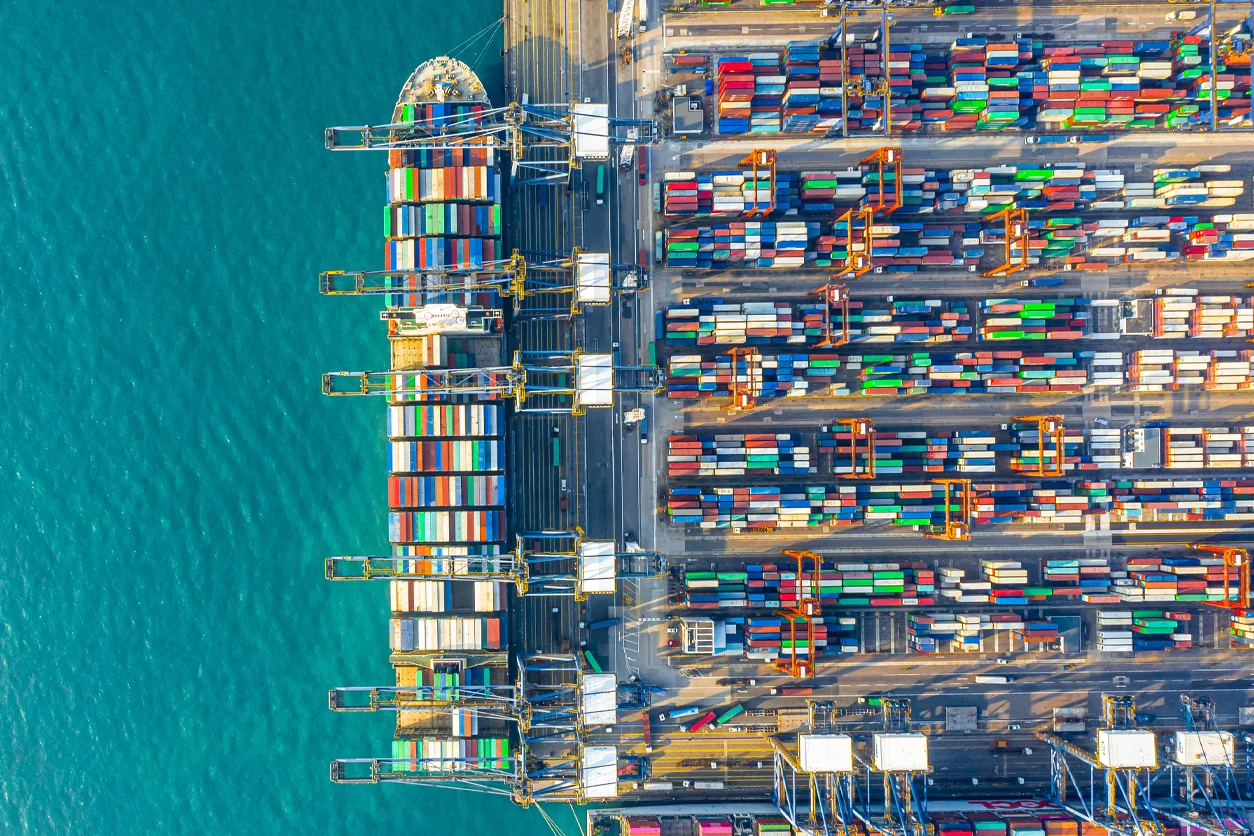

PSA Antwerp operates a number of large operations in the Port of Antwerp-Bruges. MPET (MSC PSA Antwerp European Terminal), a 50:50 venture between PSA Antwerp and TiL (Terminal Investment Limited) is Europe’s single largest container handling facility. Besides MPET, PSA fully operates 2 other container facilities directly located on the tidal river Scheldt. Together, they play a pivotal role in the global shipping industry, ensuring that thousands of shipping containers reach their destinations securely and safely each day. In addition, MPET alone handles 3000 trucks, using 38 key cranes, 230 straddle carriers, trains, and other transport to move goods and containers as efficiently and safely as possible across 242 hectares of operational yard (equivalent to 200 soccer stadiums), capable of berthing several of the world’s largest ships on any day.

Global businesses depend on PSA Antwerp to ensure that their customers receive their goods on time, anywhere in the world. The terminal runs 24 hours every day, managing 80% of containers passing through the Port of Antwerp-Bruges (10.2 million TEUs).

Being an innovative leader in the industry, PSA Antwerp is on track to becoming a one-stop-shop global supply chain provider. Its operations will include clearance and settlements, regulatory compliance, trade compliance, central logistics, predictive ETA, and all things related to the safe handling and transport of any goods to their destination as efficiently as possible, anywhere in the world.

Background

With the significant increase in global trade, the workload at PSA Antwerp continues to grow substantially. At the same time, being passionate about innovation and technology, PSA Antwerp wants to improve the efficiency and safety of the handling of goods that will place it at the pinnacle of supply chain innovation. PSA Antwerp strives to achieve operational excellence – making sure that every asset it handles arrives at the right place at exactly the right time. To achieve this, it knows it has to operate at the highest levels of efficiency for unloading, transporting, and reloading cargo onto vessels for the next step in the journey, and that technology plays a vital role in inventory management, supply chain, and performance optimization.

From 2016, PSA Antwerp used an application devised by the European technology team (EARTECH) that is responsible for maintaining several mission-critical shipping applications. The organisation was always keen on driving innovations that could help improve the operations at the terminal–like being able to accurately calculate the time it would take to load and unload items from the far side of the vessels compared to the near side.

The core application provides a single, holistic view of the status of every asset at the terminal, like:

- The exact location (including whilst in transit) of goods and containers.

- The number of cranes available for use at the terminal.

- Equipment upkeep and how reliable the equipment was at any given time.

- The number of port workers available at any given time.

- The different types of cargo being shipped and any special handling instructions.

- The number of trucks to be unloaded or reloaded.

- The number of vessels waiting to be berthed.

- The number of trains waiting at terminals to be utilised.

- Warehouse space and availability.

- Other assets that were vital to the cost efficiency and smooth running at the terminal.

The application provides real-time operational insight, performance optimizations, and the ability to perform enhanced business decision-making, based on the multitude of concurrent activities taking place at any given time. Real-time status updates help decision-makers respond to backlogs instantly, to limit the amount of productivity waste from each piece of operational machinery in the terminal and also predict when machinery needs to be serviced based on sensor information sent back to the application.

“Hazelcast Platform easily processes huge quantities of continuous, fast-moving and changing data from different sources and presents a holistic real-time view of our business operations all day, every day.”

— Patrick Snelders, Regional Technology Manager, Group Yard Crane Automation Specialist

With the vast quantities of inventory and logistics data flowing through several applications, the EARTECH team knows it needs to continuously ingest and process data extremely quickly, to provide an accurate, continuous, real-time view around the clock to ensure that operations are as fluid and efficient as possible.

Challenge

Service outages are extremely costly to the business. Personnel on the shoreside, on vessels, logistical planners, and decision-makers had to then resort to manually updating paper-based status charts and communicating over walkie-talkies with no individual team having a complete real-time view of what was happening. This resulted in backlogs and idle, and expensive machinery being unproductive, while also wasting fuel and energy. It would take days for the backlog to be removed.

The root causes of these insufficiencies were the complex and spread core application databases that were unable to ingest, process and present an up to date dashboard view based on huge volumes of high-velocity data, created from a huge amount of GPS and RFID trackers, inventory management systems, CRM systems, and a raft of other peripheral supporting services.

Solution

PSA Antwerp believed that a high-performance data platform would accelerate data reads and writes on top of their existing database and recommended that it should use the real-time data platform Hazelcast. The PSA Antwerp team decided to deploy Hazelcast Platform and observed how well compared to the previous app it was able to easily process a much larger amount of changing data from several distinct sources and present a holistic real-time view of all their business operations all day, every day, allowing them to optimise their operational efficiencies in the moment.

“Next we’ll use Hazelcast Platform to deploy machine learning models that learn from our data in real-time and make instant predictions that we never thought possible.”

— Patrick Snelders, Regional Technology Manager, Group Yard Crane Automation Specialist

For the last four years PSA Antwerp have understood how business-critical Hazelcast Platform was to run their business faster and more efficiently, the next challenge was to identify when to apply software patches, while minimizing any business impact. Updating software was vital as the patches included everything from ensuring that data was as secure as possible to updating business applications that could further streamline the management of goods and containers. In the past, PSA Antwerp found small windows of opportunity for software patching, but due to the limited time available, it was forced to apply several patches to systems at the same time rather than incrementally–resulting in failures and the inability to run its business, which led to penalties and a significant loss of revenue.

Real-Time, All the Time

The enterprise capabilities of Hazelcast Platform offers PSA Antwerp everything it needs to have a super-fast, always-on application.

Being able to apply Rolling Upgrades is critical as it allows PSA Antwerp to upgrade one cluster node at a time while the other nodes continue to run around the clock, well within the expected Service Level Agreements (SLAs), with zero impact on the business. This also gives it a window to perform extra checks, like ensuring the upgrade works with other key components rather than rushing to get the service back online.

Management Centre offers monitoring, management, and analysis of the server nodes running within the cluster. The powerful real-time dashboard allows PSA Antwerp to browse data structures and offers the ability to integrate the output into external reporting structures.

The alternative would have been to build a tool itself, which was not a feasible option, given the complexities and substantial efforts required to develop a sophisticated operational dashboard that would have to be maintained.

The ongoing threat of cybercrime also made PSA Antwerp see the value of Hazelcast Platform’s comprehensive Security Suite that offers TLS/SSL encryption for cluster members and clients, connection authentication, and role-based security. This allows users to secure every aspect of their business application that handles data.

With the commercial offering also comes a comprehensive 24/7 support contract that allowed the customer to speak to a Hazelcast expert in the event of an issue.

Feedback from PSA Antwerp was that it is very happy with their relationship with Hazelcast. They are impressed with how Hazelcast engages with it and provides the expertise it needs. The team at Hazelcast has left a lasting, positive impression with its focus on customer satisfaction.

Impact

Having a continuous, non-stop, real-time view of business operations allows decision-makers to respond quickly to situations in the moment–they can adapt and change plans in real-time, knowing that they have the most up-to-date view on their operations, around the clock–like changing what container gets loaded by which crane, for example. With greater application agility, they are able to estimate and make decisions that lead to greater efficiency and much lower costs. They can now optimize on a much more granular level and observe each incremental adjustment in real-time, to minimize the wasted time (and subsequent cost) of each asset at the terminal and remove hotspots before they impact the efficiency of the business.

Looking forward, PSA Antwerp estimates that by using Hazelcast Platform it expects to reduce operational costs of horizontal transport by 33%. Having more efficiencies will also yield benefits to the vessel operators. The increased efficiencies will result in vessels arriving and leaving the terminals earlier than previously, making PSA Antwerp one of the most efficient supply chain operations in the world and allowing them to lead their industry globally.

Futures - Gemstone Emerald Project

As part of its transition towards becoming a logistical one-stop-shop, PSA Antwerp intends to provide all services related to the transfer of goods from any location in the world to anywhere else. In the future, if it wants to integrate all systems to have a complete view of all operations and peripheral systems associated with it, it could use Hazelcast Platform as a centralized data hub that will allow shared, secured data to be processed and acted on.

With Hazelcast Platform underpinning PSA Antwerp’s shipping applications, there are many opportunities for adding even more value as it seeks to deploy more innovation to keep it ahead of its competition. Stream processing capabilities could be used to track multiple moving assets, including people, goods, containers, trains, and trucks. Being able to estimate when something will happen will offer a multitude of opportunities to become more efficient. Furthermore, with Hazelcast Platform it could deploy machine learning models that can learn from its data and even make predictions that it never thought possible.